Grinham Research Group

Harvard University Graduate School of Design

Breathing Wall

Heat Exchange with Low Carbon Materials

Project Overview

This study demonstrates how to design pores in building materials so that incoming fresh air can be efficiently tempered with low-grade heat while conduction losses are kept to a minimum. Any base material can be used in principle, so long as it can be manufactured with millimeterscale air channels. The channel-pores are optimized according to the thermal conductivity of the base material, the dimensions of the panel, and the suction pressure sustained by a given fan or a chimney. A water circuit is integrated at the interior surface to ensure direct thermal contact and prevent radiant discomfort. Correlations from the thermal sciences literature were used to optimize the size and distribution of channel-pores in wood, glass, and concrete test panels. The measurements showed good agreement with theory and were presented in a general form so that designers can predict the steady-state performance of any optimal design in sensible heat-transfer mode.

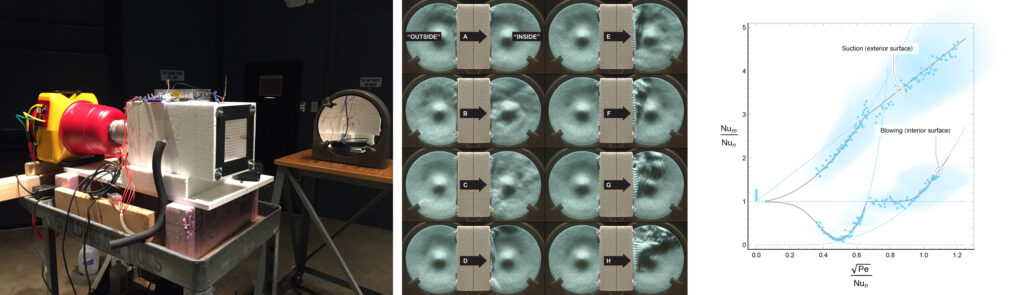

Experiment

Project Team

Jonathan Grinham

Sal Craig

Schlieren imaging was used to characterize the different regimes of mixed convection at the interior and exterior surface. The data explain the discrepancy between prediction and measurement in the dynamic insulation literature, and how the integrated water circuit overcomes these problems. Surface heat-flux measurements were correlated in a general form so that designers can account for convection at the interior and exterior surface.