Grinham Research Group

Harvard University Graduate School of Design

cSNAP

Indirect Evaporative Cooling

Project Overview

As average global temperatures steadily climb, the worldwide demand for air conditioning is expected to triple by 2050. Conventional air conditioners, while cheap to manufacture, still rely on inefficient mechanical vapor compression methods developed almost a century ago to cool and dehumidify air, making them one of the largest consumers of energy in industrialized countries. An alternative cooling method called evaporative cooling (EC) uses up to 75% less energy than vapor-compression systems, but EC only works well in relatively dry climates because it adds moisture to the cooled air, making it less effective in humid areas.

Project Journey

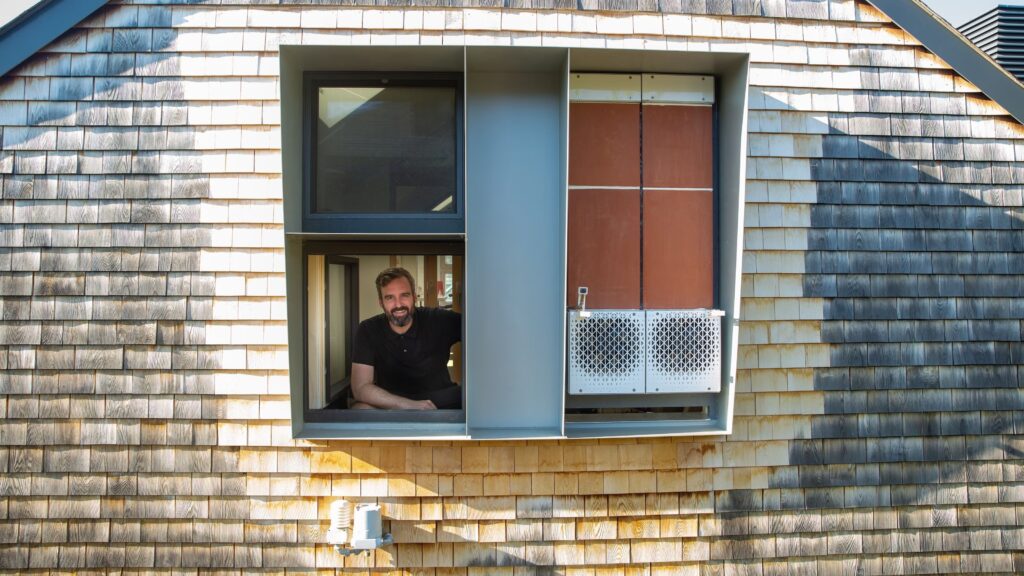

This technology is currently being de-risked at the Wyss Institute. The team is working with an industrial partner in Spain, Faveker, to develop manufacturing techniques that can be used to produce evaporative cooling units at scale. They are also working with Harvard’s HouseZero to test the technology’s cooling capabilities in real-world conditions.

Our Solution

Project Team

Jonathan Grinham

Jack Alvarenga

Katarina Richter-Lunn

Peteris Lazovskis

Martin Bechthold

Joanna Aizenberg

Our evaporative cooling technology, designed by a multidisciplinary team of scientists and designers from the Wyss Institute, Harvard’s Graduate School of Design (GSD), and the Harvard Center for Green Buildings and Cities (HCGBC) is a durable, low-cost, low-energy EC system that can work efficiently in hot and hot-humid climates, and could one day replace vapor-compression coolers with a much more environmentally friendly option. Our evaporative cooling technology’s specialized coating isolates incoming hot air from outgoing wet air, allowing the hot air to be cooled by circulating water without adding humidity to the inside of the building. Credit: Wyss Institute at Harvard University Inspired by the water repellency of duck feathers, our evaporative cooling technology consists of 3D-printed ceramic coated with a novel, nanoscale hydrophobic material. The coating effectively isolates water vapor from the air that is released into a building, preventing it from becoming humid while promoting heat transfer to maximize cooling. Our evaporative cooling technology could be integrated into existing EC coolers and sold as environmentally friendly air conditioning units in a wide variety of climate zones. It could even be manufactured into the façades of buildings, which would allow them to effectively cool the space within while only using energy to pump water and air through the system