Grinham Research Group

Harvard University Graduate School of Design

DryScreen

Vacuum Membrane Dehumidification

Project Overview

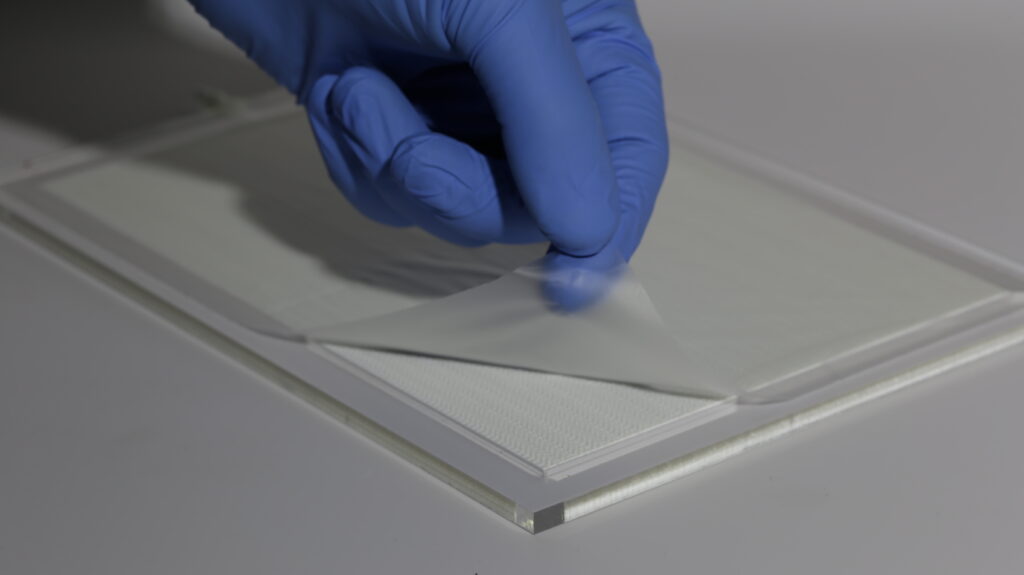

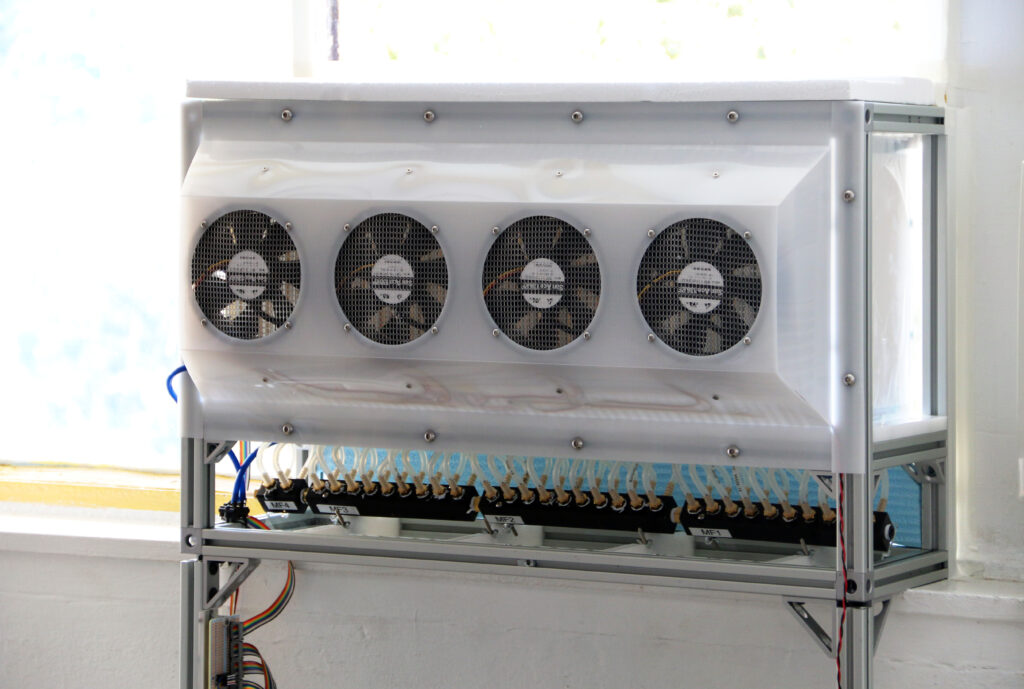

Heating, ventilation, and air conditioning (HVAC) is responsible for roughly 40% of a building’s energy use and about 20% of global carbon emissions. In hot and humid climates, traditional vapor-compression air conditioning (AC) systems use a significant amount of energy to remove moisture from the air. State-of-the-art research aims to reduce energy consumption by de-coupling these two processes to optimize them independently. Our novel technology, DryScreen, applies pressure to extract water vapor from the air through a water-selective polymer membrane. This method uses less energy, does not use high GWP refrigerant chemicals, delivers larger amounts of fresh air per unit of energy, and provides a healthy connection to the outside air.

Project Journey

Our research project has been supported by U.S. Department of Energy grant. Through a pilot field study, we have identified competitive advantages and critical pathways toward commercialization. We have established a robust network of academic collaborators, national laboratories, industry partners, and specialty materials manufacturers. Ongoing development efforts are supported through the Harvard Climate Change Solutions Fund.

Innovation

Project Team

Jonathan Grinham

Jack Alvarenga

Peteris Lazovskis

Pamela Cabrera

Manideep Rebbagondla

Les Norford

Joanna Aizenberg

We are developing and field-proving a water-selective vacuum membrane system for energy-efficient, low-carbon emission building dehumidification. As humid air passes through the system, water vapor is selectively captured using an array of mass exchangers with a specially developed polymer membrane unit. Vacuum pressure is applied to amplify the water permeation through the membrane, providing further energy reduction. By eliminating the phase-change process for water removal, our DryScreen vacuum membrane dehumidification (VMD) system is a less energy-intensive and lower life cycle GWP method than typical vapor-compression systems.