Grinham Research Group

Harvard University Graduate School of Design

Geo-stitch

New form through stitching irregular waste stone

Project Overview

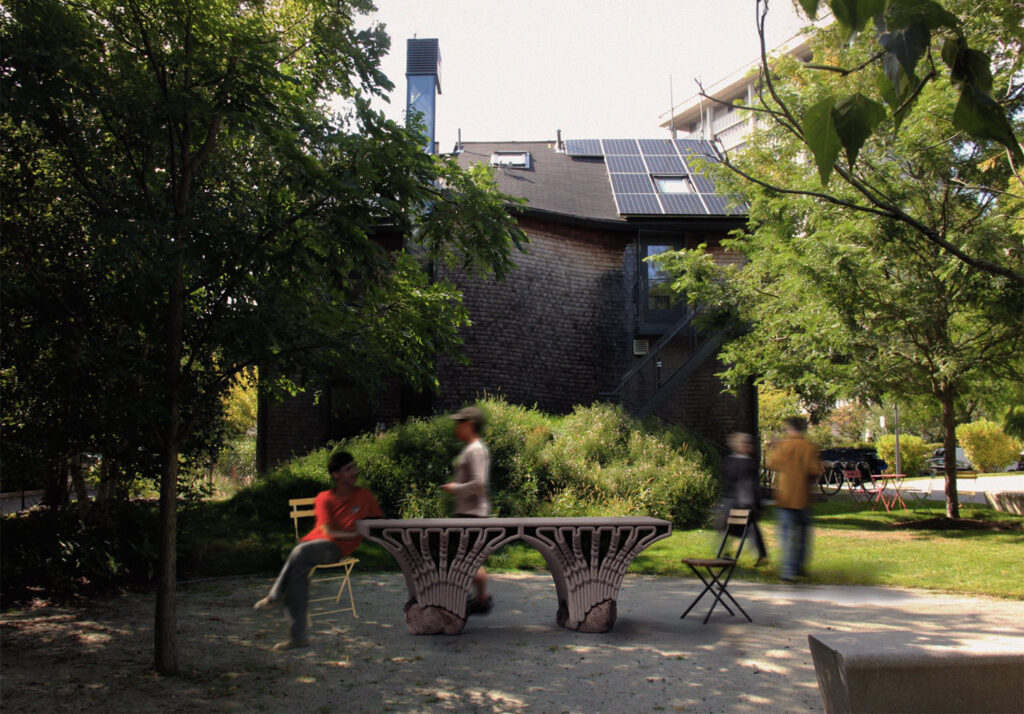

Project Geo-stitch explores architectures conceived through the restitching of waste mine tailings across a geological timescale. The research intervenes in the most recent anthro-geological cycle of the Kentucky Corbin Sandstone, which is exposed through mountain-top removal. Weathered red sandstone is pulverized as a cement aggregate, while newly unearthed grey sandstone is intelligently placed as structural elements. Geostitch then develops computation and additive manufacturing workflows to generate architectures through re-stitching the red and grey sandstones. The project allows for questions of terrestrial rehabilitation, the metabolizing of irregular stone, and the material affordances from reduced cement, formwork, and transportation in construction.

Project Journey

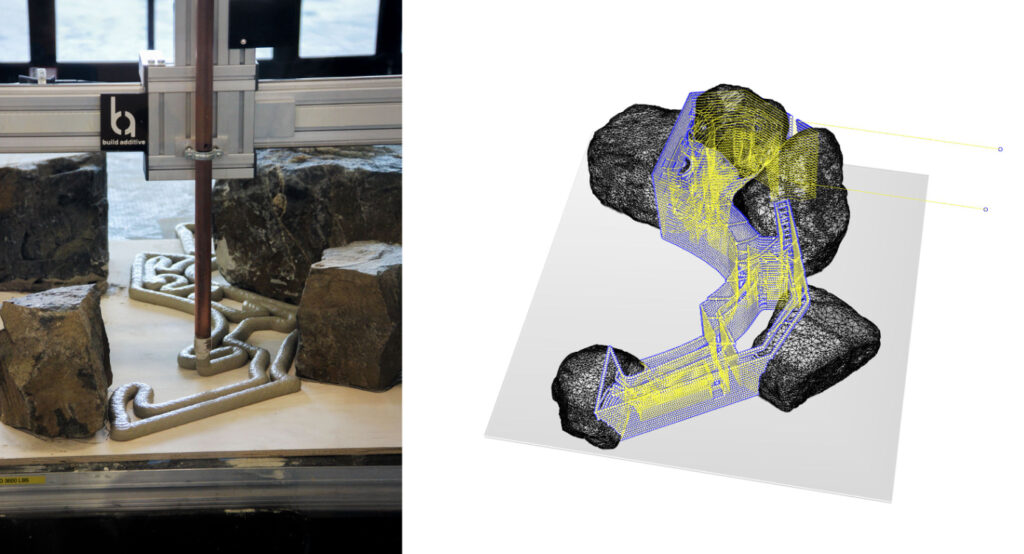

Geo-stitch began in Jonathan Grinham’s GSD Fall 2024 course “Circuits and Loops: Towards a Regenerative Architecture” and advanced into Maddie Farrer’s M. Arch I 2025 thesis Reshaping Remnants. The thesis critiques architecture’s teleological mindset, proposing a practice of material inheritance, ecological realities, and deep time: using discarded stone from post-extractive Kentucky landscapes and 3D-printing cement between irregular boulders to restore watersheds and support human and non-human needs. Building on this research, the team received a residency at Autodesk Technology Center Boston, where the final prototype is being fabricated using the Build Additive, large format cement 3D-printer. An installation of the prototype at House Zero is planned for the 2026 Spring semester.

Read more about the project here.

Fabrication

Project Team

Jonathan Grinham

Maddie Farrer

Chenming He

Tanil Raif

Collaborators

Adam Day, Autodesk

Greg MacGlashing, Autodesk

Haden Quinlan, MIT APT

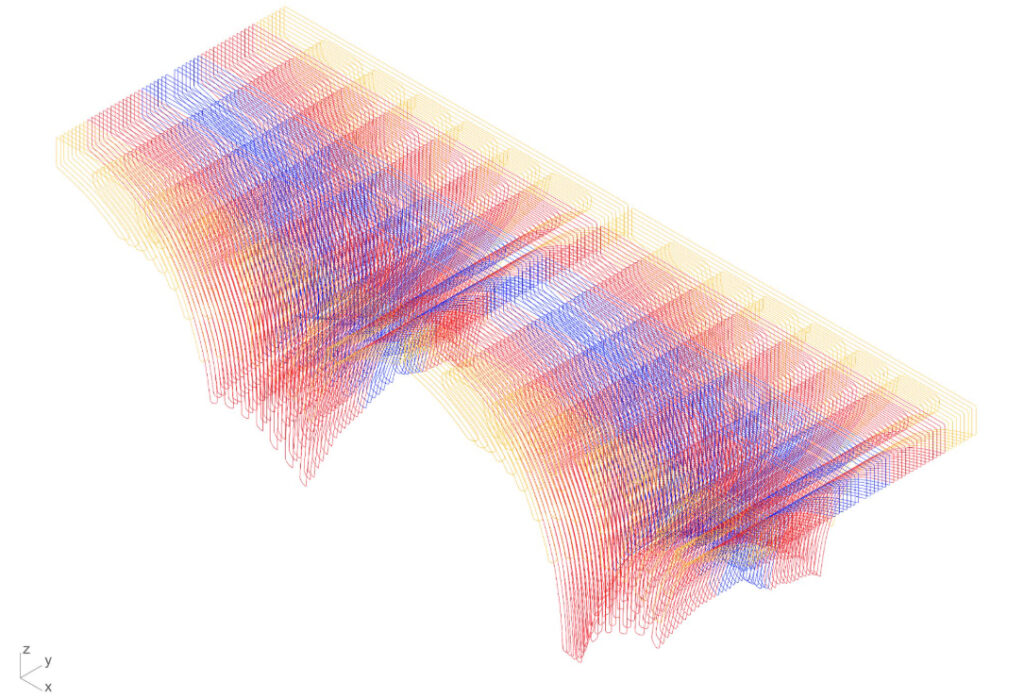

Working with Autodesk Research, MIT’s Center for Advanced Production Technologies (APT), and Build Additive, the GRG team is developing a custom 3D-printing workflow including: 1) in situ stone scanning/digitization, 2) automated tool path planning, and 3) co-printing cementitious material and stone using the large format 3-axis Build Additive Machine.