2018 Material Systems: Digital Design and Fabrication

SCI-6317 Material Systems: Digital Design and Fabrication, co-taught by Prof. Martin Bechthold and Jose Luis García del Castillo y López, positions material systems as combinations of design technologies with material processing and manipulation environments.

The translation between architectural design and the subsequent actualization process is mediated by various tools and techniques that allow design teams, fabricators and installers to engage the materiality of architecture. Over the past decade advances in material development have been catalyzed by increasingly robust implementations of digital design and fabrication techniques that have empowered designers through digital modeling, simulation, and the increasingly digital augmentation of all physical processes. Creative applications of material related technologies have produced new forms of expression in architecture, triggered a debate on digital ornament, and continue to advance the performative aspects of buildings. Yet we are only at the beginning of a new age of digital materiality…

Material systems are positioned as central to a research-based design enquiry that capitalizes on opportunities that emerge when craft-based knowledge is synthesized with CNC-machines, robotic technologies, additive manufacturing and material science. Ceramics is the first ever material created by mankind – it is omnipresent in the craft-studio as well as in industrial manufacturing settings. Pleasing to the touch and easily manipulated by hand, it can just as easily be subject to digital technologies and robotic approaches. While ceramic-specific aspects of material design and manipulation are explored, the emphasis is on understanding ceramics as a microcosm of material research that offers insights which transfer to work with almost any material used in architecture.

More images of the opening reception and the exhibition.

Material Systems: Digital Design and Fabrication, Fall 2017, Harvard University Graduate School of Design.

Course led by Prof. Martin Bechthold and Jose Luis García del Castillo y López, assisted by Ngoc Doan, Saurabh Mhatre, Chien-Min Lu, Zach Seibold and Diana Yan. In collaboration with the Harvard Ceramics Program, in consultation with Kathryn King, Geoff Booras, Mark Burns, Casey Zeng and Natalie Andrews. Exhibition curated by Chien-Min Lu and Jose Luis García del Castillo.

Supported by ASCER Tile of Spain.

Projects

01 Dynamic Multi-Material Casting

Team: Olga Geletina

This project investigates casting of patterns generated by ferrofluids. The patterns are tested in seven different compounds, namely: resin, hydro stone and drystone (both are gypsum cement), rockite (hydraulic cement), terracotta, porcelain, as well as stoneware. The work attempts to answer whether a single mould system can produce a broad variety of patterns across multiple materials. Does this process stay constant for different compounds? My conclusions were that, despite the clay’s aversion to an oil-based ferrofluid, it is possible to use slip in this method. The downsides are that it is very labor intensive. However, casting with clay bodies has its advantages, such as a higher resolution relative to the cement mixtures and a superior environmental factor especially when compared with resin. Clay also needs to be fired so cleaning out the tiles is a simpler procedure. Depending on the application, these characterizations may be favourable. For example, fine resolution porcelain can be successfully functionalized with super-hydrophobic treatment using fluoro functionalized sol-gel alumina. Collectively, the material survey has contributed to a greater understanding of the adaptivity associated with the ferrofluid casting process. The projects repeatable results suggest that a systematic characterization of different compounds is possible and that it is a dynamic process that can satisfy multiple design needs.

02 The Slime in the Machine

Team: Diana Yan, Nicole Bakker, Nathan Peters, Nic Hogan

Here we describe a system for the exploration of the interface between chaos and control through the manipulation of physarum polycephalum (slime mold) on ceramic topologies. Slime mold has gained interest across an array of fields due to its ability to solve shortest walk scenarios on varied topologies. At the beginning of its life-cycle, the species rapidly coats a surface in order to identify food sources. Once these nutrients nodes have been located, the species retract excess plasmodium, leaving thickened channels that connect each node. These channels follow the shortest-walk path between food sources on the topology with striking accuracy. By manipulating the topology of ceramic tiles, the shortest walk between food sources, and therefore the channels formed by the slime mold, can be manipulated. At exaggerated topologies with extremely high peaks, the shortest walk to a food source is more easily calculated given the severity of the gradient on steep edges. In these scenarios, the slime mold extends its channels in a predictable manner. At more subtle topologies, however, a subset of paths are accessible to the slime mold. Factors beyond shortest-walk calculations influence its decision-making process, leading to the deliberate introduction of chaos into the system. This system allows for the novel exploration of the interface between chaos and control in the design process.

03 Spaceramic

Team: Meng Jiang, Evelyn Cheng Zeng, Ziwei Song

In the course of the twenty-first century, the application of computer-aided design (CAD) and digital fabrication has radically pushed forward the boundaries of traditional architectural construction. Technological and industrial innovations have increased the possibilities for ceramics to achieve complex geometries in a mass-production manner. On the other hand, the current design practice for ceramic decorative facade system is still mostly restricted to the method of stacking or vertical aggregation. Cost and time constraints from mold making, as well as the particular nature of ceramic material property, leaves the spatial quality of decorative ceramic units to remain undiscovered. This paper presents an integrated design and digital fabrication work-flow for a customized 3D ceramic facade system. Several prototypes of fabrication method are examined, followed by an evaluation of each method and its potential for industrial mass production. The resulting design-to-manufacturing process was tested during the generation of a prototypical facade system for a canopy.

04 Hybrid Ceramic Materials

Team: Jiawen Chen, Marcus Mello, Nathalie Mitchell, Na Wang

Natural disaster mitigation, especially in regards to seismic zones, is a topic that has been widely investigated by architects, engineers, and material scientists. Studies regarding clay as a building material constitute a significant body of innovative material research, and have informed methods of both structural and modular design. Many parts of the world that build with clay are also located in seismic zones; these areas suffer from the physical destruction caused by earthquakes when they occur. Our research investigates how ceramic modules can be fabricated from fired earthenware – specifically terracotta – in seismic-prone areas, and how such modules can be strengthened with clay additives on a micro scale. Our research focuses largely around the structural characteristics of ceramics, specifically terracotta, and how the flexibility of the material can be harnessed to create interlocking modular units. Un-reinforced masonry buildings, in particular, perform poorly in earthquakes. Our research examines the microscopic and macroscopic material properties of ceramics as a building material, and seeks to improve structural characteristics (mainly compression) through explorations with additive materials.

05 Spatial Print Trajectory

Team: Sulaiman Alothman, Hyeon Ji Im, Francisco Jung

Vernacular building techniques inform us of possible ways to reinvent construction via digital fabrication. Clay is one of the oldest building materials available and has been used for construction through traditional techniques like Adobe, Clay Lump, Cordwood, Earthbag, and Rammed earth. Instead of stacking bricks or interlocking prefabricated structures, the Clay lump construction primitively piles material on top of itself resulting in a monolithic structure, very similar to the process of additive 3D printing. Current Soil Additive Manufacturing techniques are restricted to layering in 2 axes. This method inevitably uses an excess amount of building material and is a time consuming process that rarely takes into account the material properties of the soil. Spatial print trajectories can control material behavior as it is extruded by means of controlling the print speed and extrusion rate to form self-supporting complex geometries. To exploit the potential of digital fabrication at the construction scale, this research will aim to generate a modular print path with embedded parameters (ex. varying print speed along the path) in order to accommodate for the material behavior. The modular print path acts as a building block with print parameters that can be heterogeneously controlled in order to form complex geometries with different density, porosity, and structural rigidity.

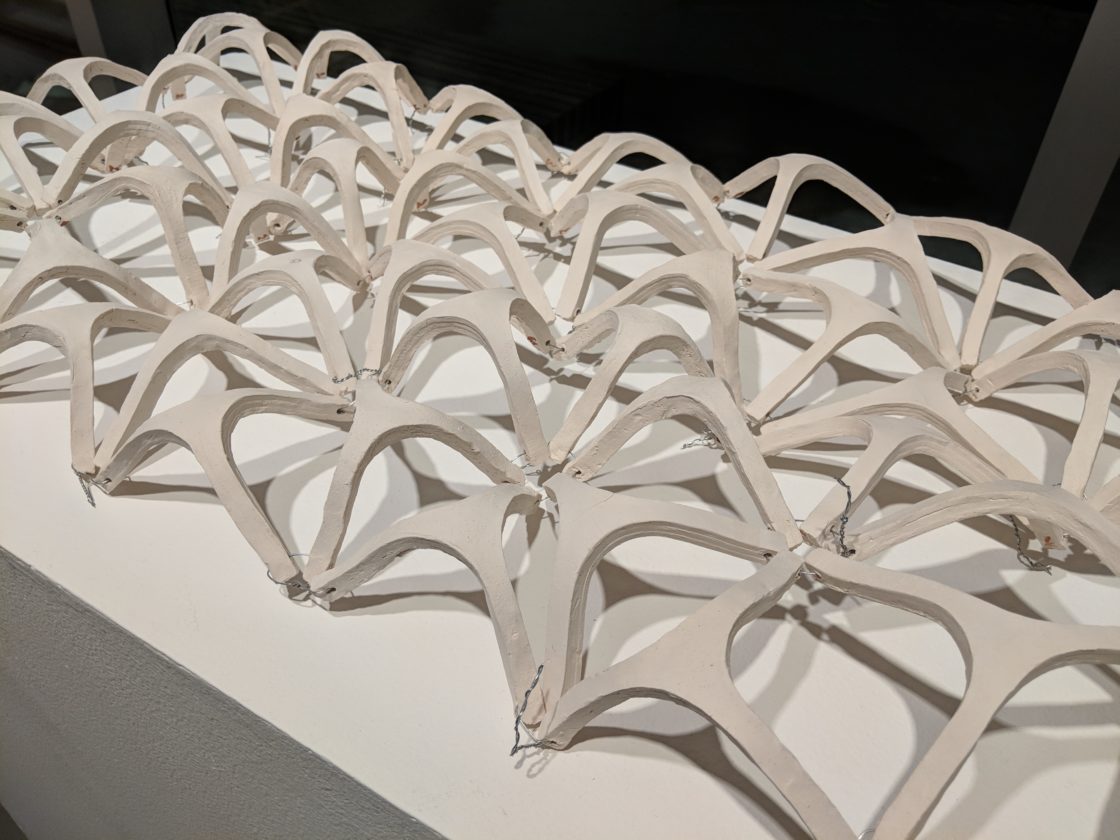

06 Ceramic Arch

Team: Lubin Liu, Yonghwan Kim, Mari Jo

Ceramic has been used for art and architecture since ancient times for its great possibilities for forms and selections of finishes and colors. Today, ceramic continues to remain a popular choice for interior surfaces. Its variety and versatility have true strength as a finish and decorative material as in the use of floor and wall tiles and facade applications. Ceramic not only has aesthetic appeal as an architectural element but also shows a potential for structural applications with its material strength in compressive force. Currently, it is used as a structural material only in brick construction, and less so in thin walled ceramic systems. The research aims to increase the adaptability and application of ceramic units in a funicular thin shell structure in an industrial production setting by introducing a digital fabrication methodology. Through the designs and construction of ceramic thin arch structure in the form of an arch, it presents the customization of form and depth in produced ceramic units and explores structural application of porcelain components in the ceramic arch designed and analyzed with the structural prediction software.

07 Ceramic In Rotation

Team: Jin Guo, Xinyun Li, Xin Zheng

In the area of customization, this paper focuses on the molding strategy that can deploy a single mold to generate a variation of units- controlled mold rotation in ceramic casting, based on the quantitative relationship established from the tests. The experiments on slip volume and drying time-variables that can affect the thickness and density in customization finally leads to the production that can be applied to the structure of force distribution, which can also be regarded as part of the further experiment in this process.

08 Evaporative Cooling Bricks

Team: Kenner Carmody, Margaret George, Ao Li, Mia Ming Guo

There is an argument to be made for the recovery of natural systems in architecture that challenge 20th century notions and modern practices of tight building envelopes and mechanically cooled buildings, regardless of the climate and context in which they are located. With the ubiquity of mechanical air-conditioning and market demand for fully glazed building facades, the modern approach to architecture and building systems comes with high costs. Architects must consider introducing suitable materials adapted to local climatic conditions to offer innovative and viable solutions to conditioning spaces in and around buildings. By dis-entombing traditional methods of construction and variable thermal comfort and by enhancing them with contemporary modes of design and fabrication, this research proposes empirical study that suggests a return to designing naturally conditioned spaces to alleviate energy loads on buildings in cooling dominated climates. The results of this iterative process of discovery are the reliable production of lightweight ceramic units forming facades and partitions using minimal amounts of material. These facades are further enriched by performance-based tectonic assemblies that allow for effective thermodynamic characteristics and unique architectural expression.

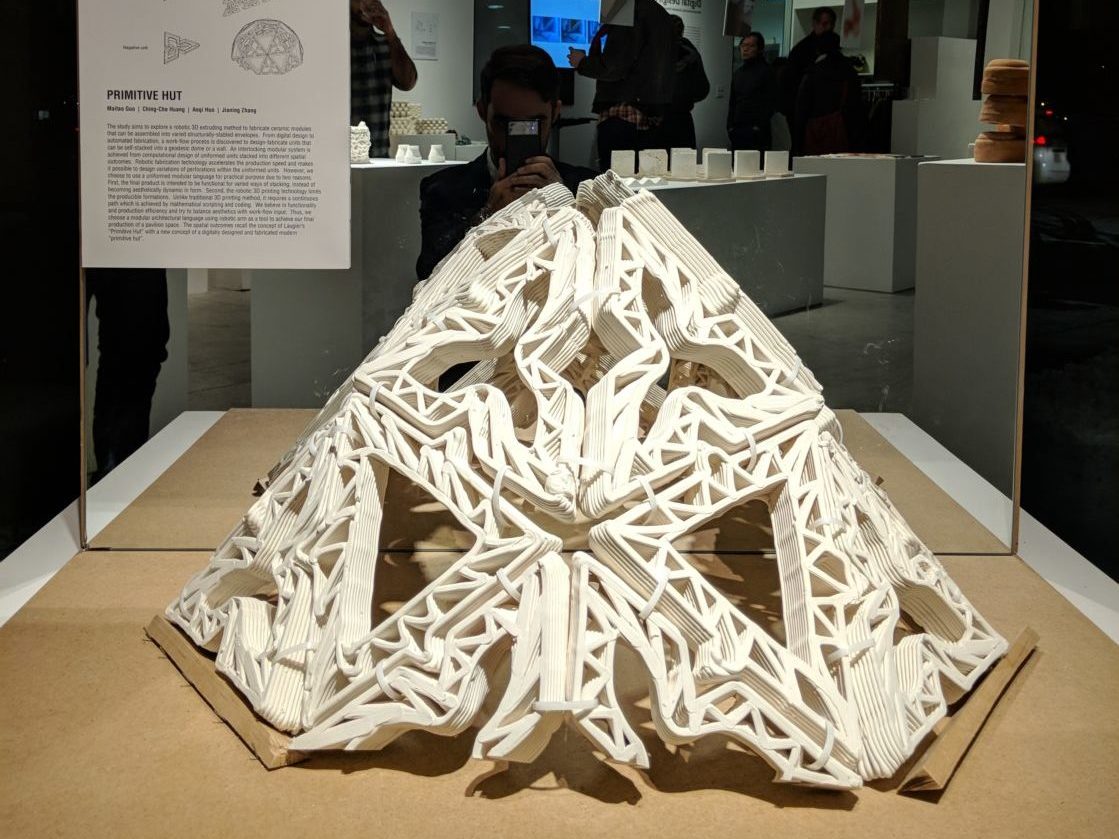

09 Primitive Hut

Team: Maitao Guo, Ching-Che Huang, Anqi Huo, Jianing Zhang

The study aims to explore a robotic 3D extruding method to fabricate ceramic modules that can be assembled into varied structurally-stabled envelopes. From digital design to automated fabrication, a work-flow process is discovered to design-fabricate units that can be self-stacked into a geodesic dome or a wall. An interlocking modular system is achieved from computational design of uniformed units stacked into different spatial outcomes. Robotic fabrication technology accelerates the production speed and makes it possible to design variations of perforations within the uniformed units. However, we choose to use a uniformed modular language for practical purpose due to two reasons. First, the final product is intended to be functional for varied ways of stacking, instead of becoming aesthetically dynamic in form. Second, the robotic 3D printing technology limits the producible formations. Unlike traditional 3D printing method, it requires a continuous path which is achieved by mathematical scripting and coding. We believe in functionality and production efficiency and try to balance aesthetics with work-flow input. Thus, we choose a modular architectural language using robotic arm as a tool to achieve our final production of a pavilion space. The spatial outcomes recall the concept of Laugier’s “Primitive Hut” with a new concept of a digitally designed and fabricated modern “primitive hut”.

10 Soft Aggregate Jamming

Team: Aurora Jensen, Iain Gordon, Peter Osborne

While a variety of high-end architectural applications for ceramics have been developed in the last few decades, the aggregation of soft clay bodies is unexplored. Drawing on the work of Gramazio & Kohler’s Remote Material Deposition Installation as an example of soft deposition and deformation, and the work of Hensel, Menges and Karola’s Aggregate Architectures at the Architecture Association in London, this study began by exploring the opportunities offered by aggregating ceramics as a building tectonic in its plastic phase. By documenting the formal and thermal properties of the variable density bricks, this research reveals the emergent qualities and flexibility of this soft aggregation process. Future research opportunities for this soft aggregate material system and potential applications in architecture are discussed.

11 Pappardelle Pillars

Team: Andrew Bako, Alexandru Vilcu

Throughout the past five decades, architectural construction has seen an exponential increase in the use of automated systems to employ methods of mass customization. However, while serving as an effective method to reproduce standard components, until very recently, these technologies have been underutilized in the production of custom components. In contemporary design practice, the newfound pervasiveness of digital fabrication has enabled designers to perform experiments in customization and serial production. Buildings such as the Broad by Diller, Scofidio, and Renfro are not only examples of the possibility for customization, (managed by digital methods in design and fabrication), but also serve as examples of the ubiquity of such techniques due to their employment at a large scale. Moving forward, the emergence of mass customization provides agency to architectural ornamentation once again, an aspect of the discipline largely ignored and scrutinized due to the modern movement’s minimalist agenda.

12 The Mixology Table

Team: Jiho Sejung Song, Haeyoung Kim, HyeJi Yang

Ceramic material has long been used as the medium to purify water and it has expanded its territory to air filtration system. Such properties as porosity allowing the flow and resistance to corrosion let on the various research topics in ceramic as an effective filter agency. Although architecture has exploited ceramics in numerous ways in history, there still exist certain parameters of the material worth exploring for architectural application. The filtration capacity of ceramics might be able to offer a new opportunity for controlling air, water, light, and sound conditions. This research explores porosity of ceramic as a means of a potential architectural filtration system. The emphasis is set on controlling a scale and position of porosity in ceramics from nano-porous: the inherent property of ceramics, to micro-porous: the engineered property of ceramics. The level of nano-porosity is experimented through differentiating the thermal curing temperature of a kiln. The size of micro-porosity is dependent on the size of a swollen hydrogel and its position is specified through the rotation and time. Future research opportunities for this controlling porosity of ceramic and potential applications in architecture are discussed.