Janus Printing: Co-extrusion based Multi-material Additive Manufacturing for Ceramics

How can we deposit multiple clay bodies with a single integrated design to 3D printing process? While the context for this project is the growing area of functionally graded materials and multi-material processes the work began by looking back in time. A historic example of tiles with multiple clay bodies are encaustic tiles. They feature full-body ornamentation produced by manually impressing a stencil pattern into unfired clay tiles. The resultant intaglio pattern was subsequently filled with a clay body of another color to produce ornamental tiles without the use of a glaze, resulting in elaborately detailed and durable products.

Janus Printing presents a low cost, simple means of multi-material fabrication for ceramics based on the principle of co-extrusion. This process is defined as the simultaneous extrusion, through the same die, of two or more materials. A major application is the production of food products with variable texture flavor or color with relatively simple tooling.

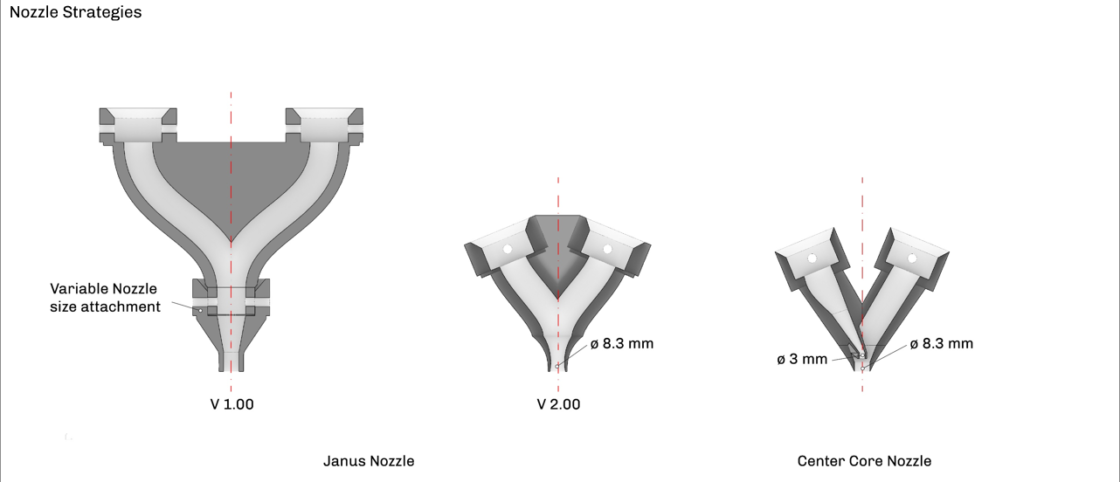

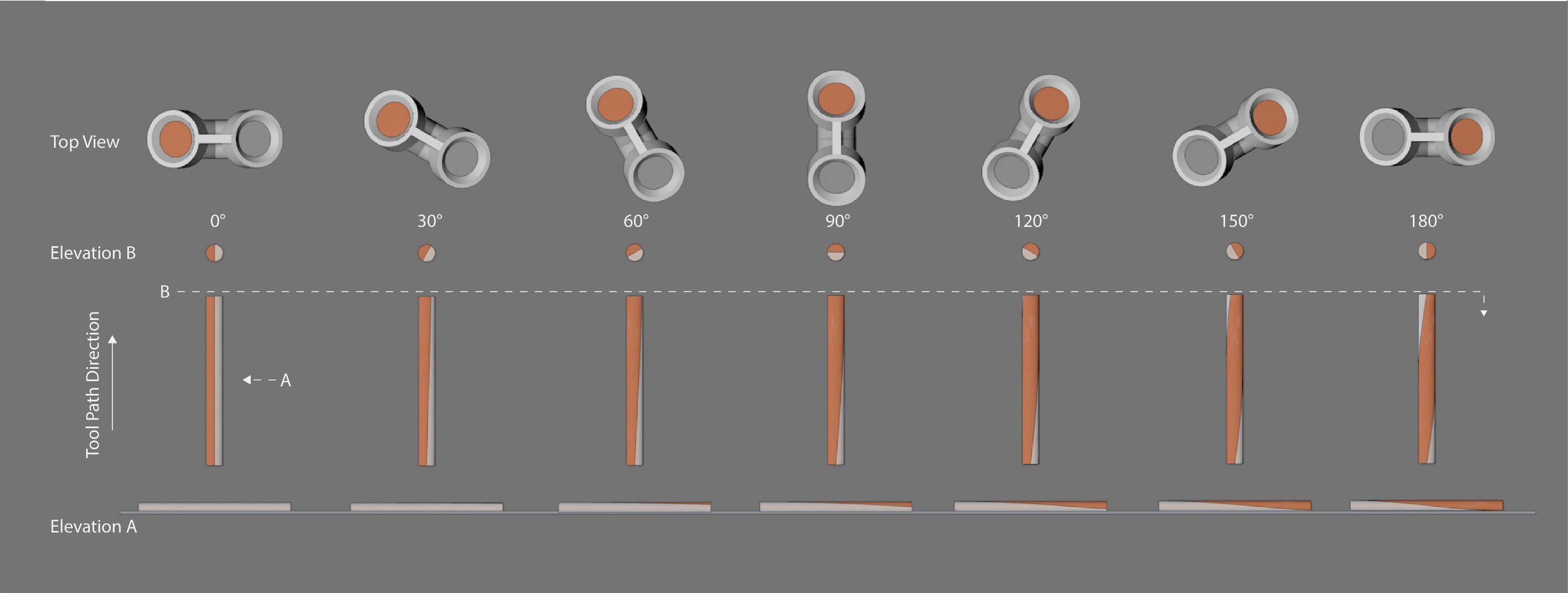

In coextrusion, the design of the nozzle is a key consideration controlling how the materials ultimately combine. The interior nozzle space and the nozzle tip geometry are key parameters. Our team produced several nozzle prototypes and experimented with printing in different orientations and angles. Angled printing turned out to be better as it not only reduces the length of travel from individual cylinders to the final nozzle, but also reduces the material travel length after the point of intersection.

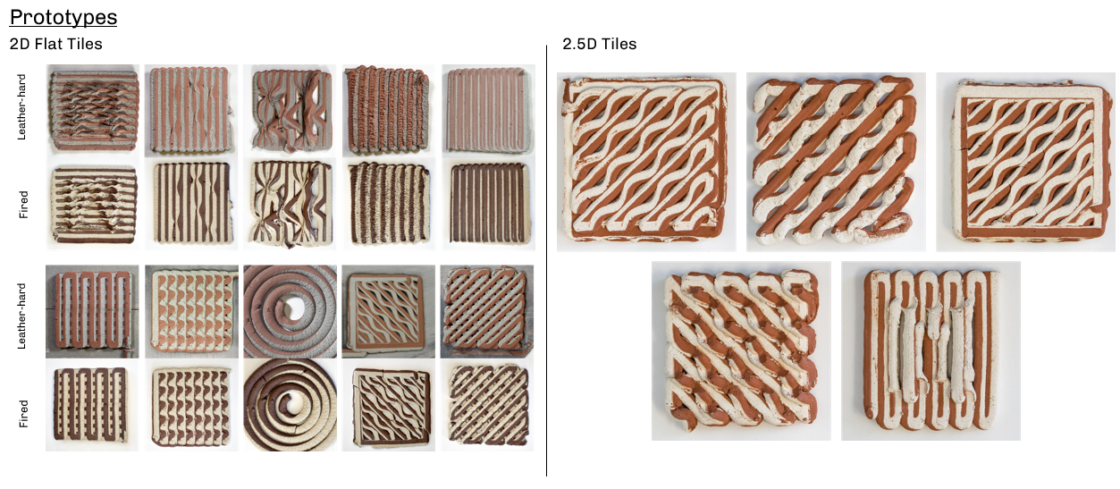

The Janus nozzle currently prints two materials side by side, while the center core nozzle prints one material inside another. Our prototypes were fabricated largely with the side by side nozzle – leading to the well known Janus effect!

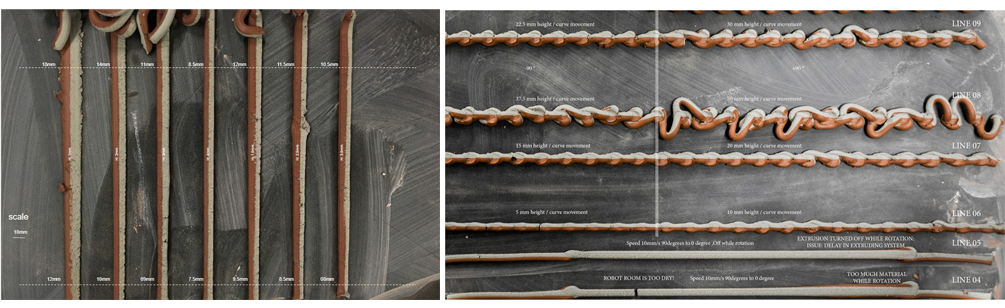

Multiple tests were performed to explore the design space of the Janus co-extrusion. The relationship of layer height and extrusion speed on the bead width was studied in depth, modifying parameters such as displacement in the z-direction, print speed, z-offset, bead width, and others.

Both clay bodies were extruded at the same rate during the deposition process.

2D tiles were printed tiles to explore the design possibilities of the workflow. All were derived through a continuous toolpath.

3D objects were made via a Rhino + Grasshopper workflow facilitated by using MACHINA.

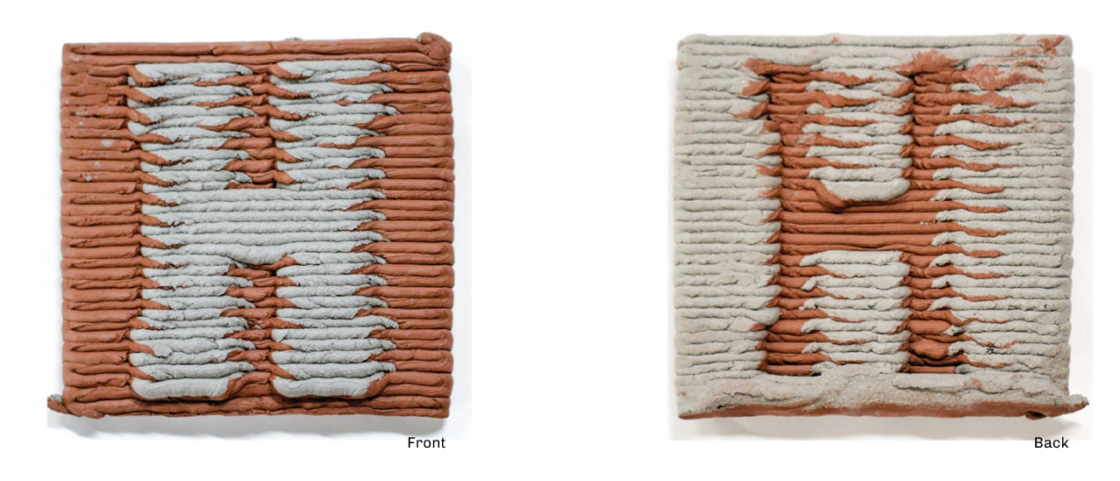

The team assessed the impact of the orientation of the nozzle with respect to the toolpath direction. The deposition of a particular body of clay within the Janus bead can be controlled with high accuracy.

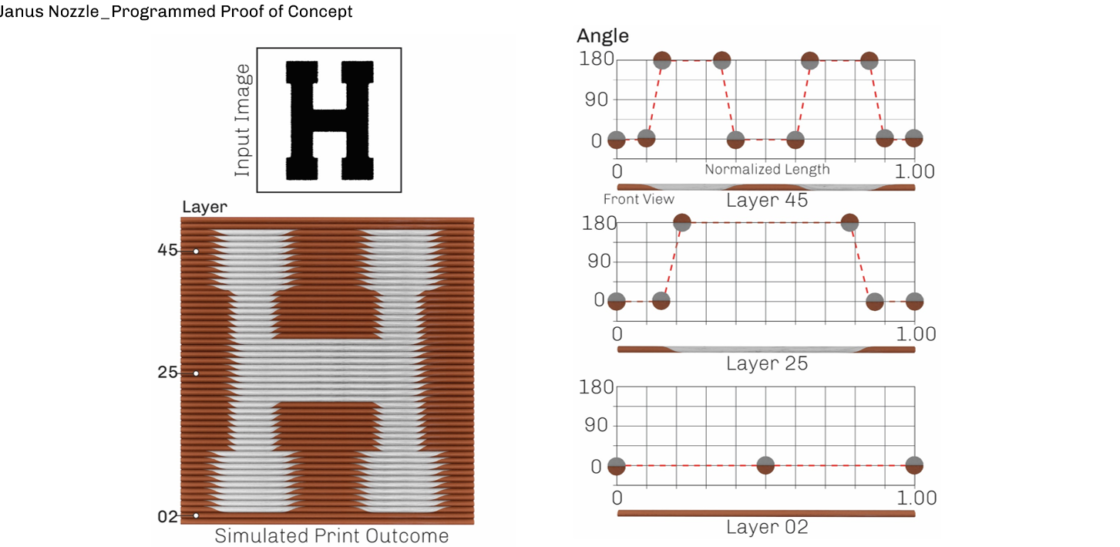

As a proof of concept, we decided to use an image as input – the Harvard H was an obvious choice! The integrated digital workflow generated the RAPID code to drive the ABB robot. The graphs show the relation of the nozzle orientation of 3 representative layers to the clay body deposited in the elevation. The tile was printed vertically to avoid the effects of cracking and warping while drying.

By incorporating a dual-material nozzle and 4th axis into the printing setup, we introduce a low-complexity, controlled means of multi-material paste-based ceramic AMTs. The computational workflow provides the means of generating recognizable images in printed samples, demonstrates a degree of control of the printed material, and generates unique visual effects that are difficult or impossible to produce by other means. Check out the paper for more details!

Publication:

Seibold, Z; Mhatre, S; Alhadidi, S; García del Castillo y López, J.L; Bechthold, M: “Janus Printing: Co-extrusion based Multi-material Additive Manufacturing for Ceramics” in ACADIA 19:UBIQUITY AND AUTONOMY [Proceedings of the 39th Annual Conference of the Association for Computer-Aided Design in Architecture (ACADIA) ISBN 978-0-578-59179-7] (The University of Texas at Austin School of Architecture, Austin, Texas 21-26 ,October, 2019) pp. 576-585

Project Team: Saurabh Mhatre; Zach Seibold; Suleiman Alhadidi; Jose Luis García del Castillo y López; Martin Bechthold.

Sponsor: ASCER Tile of Spain